Energy storage systems (ESS) are critical for grid stability as renewable energy adoption accelerates, but safety concerns have emerged due to fire hazards in lithium-ion batteries. Korea Electric Power Corporation (KEPCO) has developed an innovative solution called the Battery Intelligence Management System (BiMS), which provides real-time monitoring and diagnostics to prevent battery failures while extending operational lifespan. The modern world has thrived on the foundation of a stable electricity supply. However, as global efforts to combat climate change and achieve carbon neutrality accelerate, renewable energy sources such as solar and wind power are expanding rapidly. While this shift is essential for a sustainable future, it introduces new challenges to power grid stability due to the inherent variability of renewable generation. To maintain grid stability, electricity generation and consumption must be constantly adjusted in real-time to keep frequency fluctuations within acceptable limits. This is where energy storage systems (ESS) play a critical role. By storing excess electricity and discharging it when needed, ESS helps bridge the gap between variable renewable generation and consistent energy demand. Compared to conventional grid-balancing solutions, ESS offers several advantages, including shorter construction times and rapid response capabilities. These benefits, combined with advances in battery technology, have fueled the rapid growth of the global ESS market.

KEPCO’s Pioneering Efforts in ESS Deployment

Korea Electric Power Corporation (KEPCO) has been a leader in ESS deployment. In 2014, it became the first in the world to integrate a 24-MW frequency regulation ESS (FR-ESS) into a national power grid for commercial operation. Since then, KEPCO has expanded its ESS capacity, reaching a total of 376 MW, demonstrating its commitment to advancing energy storage technologies and adapting to the evolving energy landscape. However, as ESS adoption surged, a critical issue emerged—fire hazards linked to lithium-ion batteries. Since the introduction of ESS in Korea, at least 52 fire incidents have been reported, leading to significant concerns about the safety of ESS installations. Due to these risks, KEPCO was forced to suspend its FR-ESS operations, while the government launched multiple investigations to determine the root causes of these fires. Despite extensive research and recommendations for preventive measures, a definitive solution remained elusive.

Development of the Battery Intelligence Management System

To address the safety concerns, KEPCO took proactive steps to develop an innovative monitoring and diagnostic system. Instead of relying solely on battery manufacturers to resolve safety issues, KEPCO sought to empower ESS operators with real-time insights into battery health and performance. The goal was not only to enhance safety but also to extend battery lifespan and optimize ESS operation for long-term sustainability. One of the primary causes of ESS fires is thermal runaway, a phenomenon where excessive heat generated within a battery cell leads to a chain reaction, potentially resulting in catastrophic failure. Thermal runaway can be triggered by several factors, including internal short circuits, overcharging, and cooling system malfunctions. Given these risks, KEPCO needed a solution that could detect early warning signs, predict potential failures, and enable preemptive actions before critical failures occur. In 2020, alongside its plan to deploy an additional 1 GW of grid-stabilization ESS (KEPCO Grid-ESS, or KG-ESS), KEPCO initiated the development of the Battery Intelligence Management System (BiMS). This system was designed to move beyond traditional manufacturer-driven diagnostics, providing operators with a comprehensive and real-time battery monitoring system. The key objectives of BiMS were:

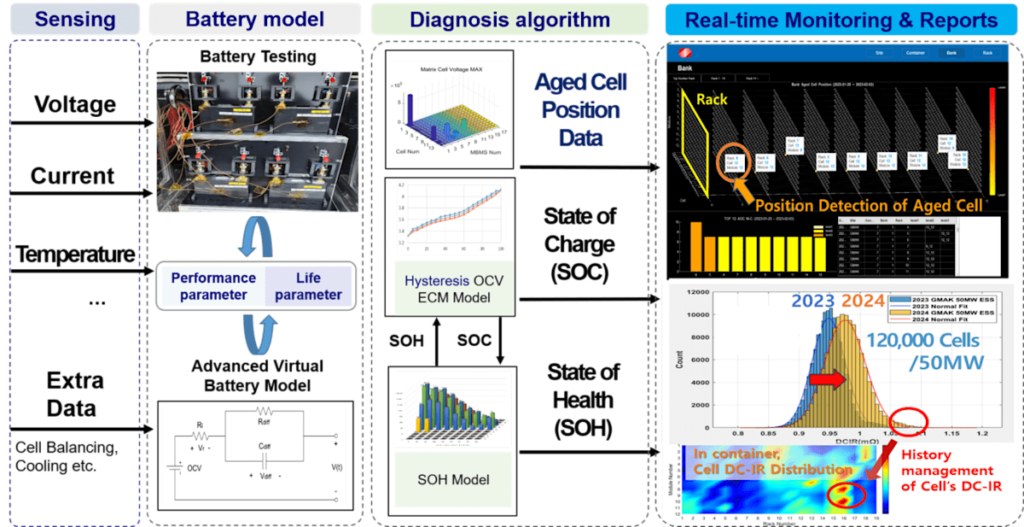

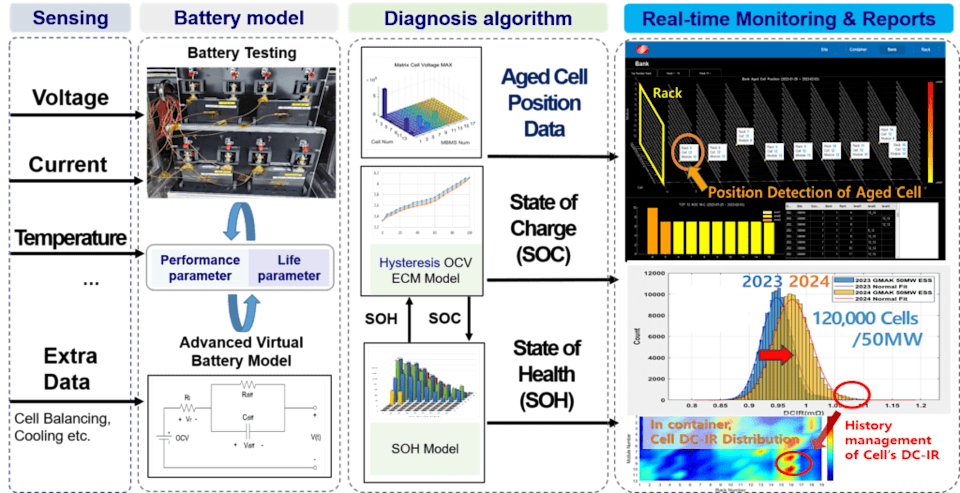

How BiMS Works

BiMS is an advanced monitoring and diagnostic system that continuously analyzes lithium-ion battery voltage, current, and temperature data. By leveraging real-time data acquisition and predictive analytics, it enables precise assessment of battery health and enhances overall ESS reliability. The internal state of a battery is often a “black box,” meaning its condition cannot be directly observed until it is physically opened for inspection. To address this challenge, the BiMS operates in KEPCO’s MW-scale KG-ESS installations, where it performs three core functions:

By integrating these capabilities, BiMS helps operators monitor battery status in real-time, detect early signs of failure, and extend battery lifespan—ensuring safer and more reliable ESS operations.

System Architecture and Data Processing

BiMS is designed to function independently of existing ESS automatic control systems, ensuring zero interference with core ESS operations. The system integrates with ESS infrastructure via Modbus communication (Figure 1), gathering real-time data from up to 150,000 battery cells (for a 56-MW ESS). The collected data is stored on dedicated servers, where BiMS applies sophisticated analytical models that account for site-specific environmental conditions. The results are visualized in an intuitive interface, providing operators with actionable insights into battery health and performance trends. By leveraging BiMS, operators can:

1. System configuration diagram of Korea Electric Power Corporation (KEPCO) grid-stabilization energy storage system (KG-ESS) and Battery Intelligence Management System (BiMS). Courtesy: KEPCO

Delivering Actionable Insights for ESS Operators

Ultimately, BiMS provides ESS operators with two key insights: an accurate assessment of the battery’s current condition and a detailed analysis of degraded cells (Figure 2). The system’s intuitive interface allows operators to monitor battery charge levels, temperatures, charge/discharge history, and daily stress indices in real-time. Additionally, by leveraging information on degraded cell locations and risk levels, operators can optimize charge/discharge schedules and maintenance plans to ensure safer and more reliable ESS operations. This proactive approach not only enhances system reliability but also significantly reduces the risk of unexpected failures, positioning BiMS as a game-changing tool for the future of energy storage system management.

2. How KEPCO’s BiMS works. Courtesy: KEPCO

Real-World Application and Expansion

BiMS has already been deployed across six KG-ESS sites (a total of 978 MW) and two FR-ESS sites (a total of 74 MW). In these locations, BiMS has demonstrated its effectiveness by enhancing diagnostic accuracy, reducing unexpected failures, and improving asset management planning. The system is continuously collecting field data, enabling KEPCO to refine and upgrade its predictive models further. Building on this success, KEPCO has committed to expanding BiMS deployment, with an additional five ESS sites (a total of 300 MW) scheduled for implementation by 2026. Furthermore, KEPCO aims to apply BiMS to ESS facilities in its overseas renewable energy projects, strengthening its position as a global leader in safe and efficient energy storage solutions.

Future Developments and Battery Lifecycle Management

Beyond its current functionalities, BiMS is expected to play a pivotal role in the future of ESS lifecycle management. As KEPCO’s ESS installations mature, an increasing number of batteries will reach the end of their manufacturer-guaranteed lifespan. Instead of discarding these batteries, KEPCO plans to leverage BiMS for detailed health assessments, determining which batteries can be reused or repurposed for alternative applications. For instance, KEPCO owns several aging ESS facilities, including the Shin-Gyeryong 24-MW ESS, which has been in operation for more than a decade. Rather than decommissioning the facility, KEPCO intends to explore innovative repurposing strategies, such as reconfiguring old batteries for low-power, long-duration storage applications or selectively refurbishing modules for secondary use. This approach aligns with KEPCO’s broader vision of promoting circular economy principles in the energy storage industry. As the global energy transition accelerates, the demand for safe, reliable, and efficient energy storage solutions will continue to grow. With its BiMS, KEPCO has taken a crucial step toward mitigating ESS safety risks while maximizing battery performance and longevity. By integrating real-time diagnostics, predictive analytics, and lifecycle management capabilities, ABCS not only enhances ESS safety, but also contributes to a more sustainable energy infrastructure. Moving forward, KEPCO remains committed to continuous innovation and expansion of the BiMS, ensuring that energy storage systems remain a cornerstone of the future power grid. Through ongoing research, technological advancements, and strategic deployment, KEPCO will lead the charge in making ESS safer, more efficient, and more economically viable for utilities worldwide.

—This article was contributed to POWER by KEPCO’s Research Institute (KEPRI) and Global Business Department. KEPCO is a state-owned electric utility company in the Republic of Korea. For more information, contact: [email protected].

Read the full article here